5 Best 4-Way Hose Splitter In 2025

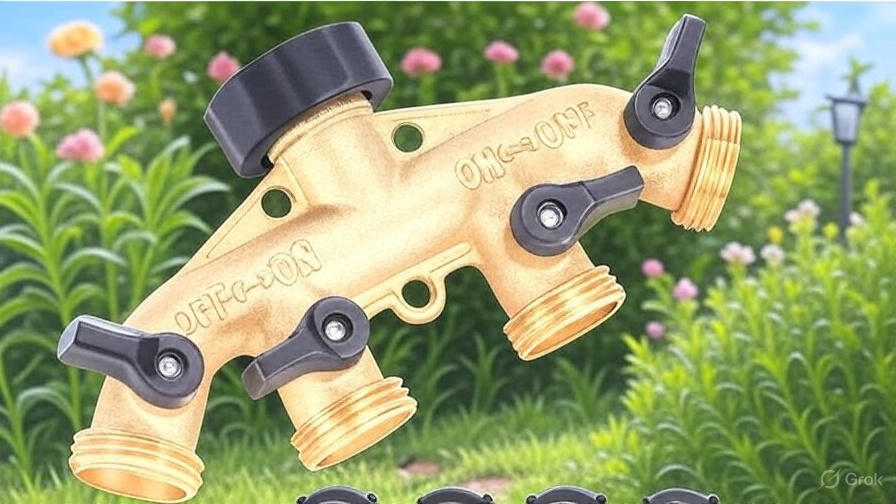

Garden watering becomes significantly easier with the right equipment. A 4-way hose splitter transforms one water source into four independent streams, allowing homeowners to water multiple areas simultaneously. These devices eliminate the need for constant hose switching and provide precise control over water distribution across different garden zones.

Professional landscapers and home gardening enthusiasts rely on these tools to streamline their watering routines. The ability to connect four separate hoses or attachments to a single spigot saves time and reduces physical strain. Quality splitters maintain consistent water pressure while offering individual valve control for each output.

What Makes a Superior Hose Splitter

Durability stands as the primary concern when evaluating hose manifolds. Brass construction offers superior longevity compared to plastic alternatives, resisting corrosion and maintaining structural integrity under pressure. Quality brass splitters withstand extreme temperatures without cracking or warping.

Thread compatibility ensures proper connection to standard garden hoses and faucets. The 3/4-inch GHT (Garden Hose Thread) standard provides universal compatibility across most residential water systems. Properly threaded connections prevent leaks and maintain optimal water pressure throughout the system.

Valve design directly impacts user experience and water control precision. Individual shut-off valves allow users to direct water flow to specific zones while keeping unused outlets closed. Extended handles provide better grip and easier operation, particularly beneficial for users with limited hand strength.

Leak prevention relies heavily on quality rubber washers and precision manufacturing. Premium splitters include multiple spare washers to maintain tight seals over extended use. Well-designed gasket systems prevent water waste and maintain consistent pressure across all outputs.

Top 4-Way Hose Splitter Reviews

1. Hourleey Brass Garden Hose Splitter – Premium Choice

The Hourleey brass splitter represents solid construction and reliable performance. This unit features heavy-duty brass construction throughout, ensuring exceptional durability against weather extremes and regular use. The solid brass body resists corrosion while maintaining structural integrity under high water pressure.

Four individual valves provide independent control over each output, allowing precise water distribution management. Each valve operates smoothly with minimal effort required for opening and closing. The design accommodates various watering schedules and different irrigation needs simultaneously.

Installation proves straightforward with standard 3/4-inch threading that connects securely to most garden faucets and hoses. The threading maintains tight seals without requiring excessive force during attachment. Quality construction ensures threads remain intact through multiple connections and disconnections.

The package includes four extra rubber washers, demonstrating the manufacturer’s commitment to long-term functionality. These spare washers replace worn seals and maintain leak-free operation over extended periods. The inclusion of extras shows attention to common maintenance needs.

Water pressure distribution remains consistent across all four outlets during testing. Users report stable flow rates even when operating all four connections simultaneously. The brass construction maintains pressure integrity without significant drops across individual lines.

Temperature resistance proves exceptional, with the unit functioning properly in both freezing conditions and extreme heat. The brass material expands and contracts uniformly, preventing cracks or joint failures common in lesser materials.

Pros:

- Solid brass construction ensures long-lasting durability

- Smooth valve operation with minimal effort required

- Includes spare washers for extended maintenance

- Maintains consistent pressure across all outlets

- Standard threading fits most garden equipment

Cons:

- Higher price point compared to plastic alternatives

- Heavier weight may stress some faucet connections

- Limited handle length for users with grip issues

2. Heavy Duty Brass Garden Hose Splitter – Value Champion

This heavy-duty brass splitter combines affordability with solid performance characteristics. The brass construction provides excellent corrosion resistance while maintaining competitive pricing. Users seeking reliable performance without premium costs find this option particularly appealing.

Four individual valves control water flow to each outlet independently. Valve operation requires moderate effort but provides secure shut-off capabilities. The design prevents accidental activation while ensuring positive closure when valves are turned off.

Standard 3/4-inch threading accommodates most residential garden hoses and spigots. Connection quality remains secure without requiring professional installation tools. The threading pattern matches industry standards for compatibility across various brands.

Water flow consistency meets expectations for typical residential applications. Pressure drops remain minimal when operating multiple outlets simultaneously. Performance suits most home watering needs without requiring commercial-grade specifications.

Durability testing reveals solid construction capable of handling regular use. The brass body resists impact damage and maintains structural integrity under normal operating pressures. Users report satisfactory longevity with proper maintenance and seasonal storage.

Temperature performance proves adequate for standard climate conditions. The unit functions properly within typical seasonal temperature ranges. Extreme climate testing shows acceptable performance with minor limitations in severe conditions.

Pros:

- Competitive pricing with brass construction

- Adequate performance for typical home use

- Standard threading for universal compatibility

- Solid build quality for the price point

- Reasonable pressure distribution

Cons:

- Valve operation requires more effort than premium models

- Limited temperature extremes performance

- Basic packaging without spare components

3.Green Handle Hose Manifold – Ergonomic Excellence

The green handle design prioritizes user comfort and ease of operation. Extended handle length provides superior leverage for valve operation, particularly beneficial for users with arthritis or limited grip strength. The ergonomic design reduces hand fatigue during frequent use.

Rust and freeze resistance capabilities extend operational seasons beyond typical limitations. The specialized coating protects against corrosion while maintaining functionality in cold weather conditions. Users in harsh climates benefit from extended operational periods.

Heavy-duty brass construction ensures structural integrity under demanding conditions. The robust build quality handles high water pressure and frequent valve cycling. Professional landscapers appreciate the durability for commercial applications.

Four individual valves operate smoothly with the extended green handles providing excellent grip surface. Handle design prevents slipping during wet conditions, maintaining control precision. Color coding helps identify specific outlet assignments for organized watering systems.

Pressure distribution remains stable across all four outlets during simultaneous operation. Flow rates stay consistent without significant pressure drops affecting performance. The internal design maintains hydraulic efficiency throughout the manifold.

Installation simplicity supports quick setup and removal for seasonal storage. Standard threading patterns ensure compatibility with existing equipment. Users report easy connection procedures without specialized tools.

Pros:

- Extended handles improve operation comfort

- Rust and freeze resistant coating

- Color-coded handles for organization

- Smooth valve operation with good leverage

- Maintains pressure consistency

Cons:

- Larger size may not fit tight spaces

- Handle extension increases overall footprint

- Limited color options for different preferences

4. EBH Extended Handle Brass Splitter – Professional Grade

The EBH splitter targets professional users requiring superior performance and durability. Extended metal handles provide exceptional leverage for valve operation under high-pressure conditions. The professional-grade construction handles demanding commercial applications.

Individual on/off valve spouts offer precise control over water distribution to multiple zones. Each valve operates independently with positive shut-off characteristics preventing water waste. The design accommodates complex irrigation schedules and varying water requirements.

Heavy-duty construction utilizes premium brass materials throughout the assembly. Structural integrity remains intact under continuous high-pressure operation. Professional installers rely on this durability for commercial and residential projects.

The outdoor faucet manifold design integrates seamlessly with existing irrigation systems. Mounting considerations allow for permanent installation in dedicated irrigation setups. Compatibility extends across various professional watering systems.

Extended metal handles resist bending and provide consistent operation over extended periods. Handle design accommodates gloved operation for professional landscaping applications. Durability testing confirms handle integrity under demanding conditions.

Water pressure maintenance exceeds typical residential requirements, supporting professional applications. Flow distribution remains consistent across all outlets during peak demand periods. Hydraulic efficiency supports multiple high-flow attachments simultaneously.

Pros:

- Professional-grade construction quality

- Extended metal handles for superior leverage

- Excellent pressure maintenance under load

- Suitable for commercial applications

- Positive valve shut-off characteristics

Cons:

- Premium pricing reflects professional specifications

- Larger size may overwhelm residential installations

- Heavy construction requires sturdy mounting

5. Complete Hose Splitter Set – Maximum Value

The complete set approach provides comprehensive watering system components in one package. Four garden hose extension adapters expand connection possibilities beyond basic splitter functionality. The comprehensive kit eliminates separate component purchases.

Twelve rubber washers ensure extended maintenance coverage for multiple seasons. Generous washer supply prevents common leak issues and maintains system integrity. Four tape rolls provide additional sealing support for challenging connections.

Brass construction maintains quality standards while offering complete system components. The splitter portion matches performance expectations for residential applications. Additional components complement the basic splitter with practical accessories.

Four individual valves control water flow with standard operation characteristics. Valve performance meets typical residential requirements without exceptional features. Basic operation suits straightforward watering applications effectively.

Extension adapters provide flexibility for complex watering arrangements. Connection options expand beyond basic hose attachments to specialized watering tools. System versatility increases with the additional adapter components.

Hose protector components prevent kinking and extend hose life expectancy. Protection features reduce replacement costs and improve system reliability. Long-term value increases through component protection measures.

Pros:

- Comprehensive kit includes multiple components

- Generous supply of replacement washers

- Extension adapters increase versatility

- Hose protection features included

- Good value for complete system setup

Cons:

- Basic splitter performance compared to specialized models

- Storage requirements increase with multiple components

- Component quality varies across kit pieces

Installation and Setup Guide

Proper installation ensures optimal performance and prevents common issues. Begin by shutting off water supply at the main valve before connecting the splitter. This prevents pressure surges during installation and protects both equipment and user safety.

Thread inspection prevents cross-threading and connection damage. Examine both male and female threads for debris or damage before assembly. Clean threads with a wire brush if necessary to ensure smooth connection.

Hand-tightening provides adequate connection strength without over-torquing. Excessive force can damage threads or compress washers beyond optimal sealing capacity. A quarter-turn past hand-tight typically provides secure connection without stress.

Washer placement requires attention to orientation and condition. Install washers with the beveled edge facing the connection point for optimal sealing. Replace washers showing wear, cracking, or permanent compression.

Testing procedures verify proper installation and leak detection. Turn on water supply gradually while checking all connections for leaks. Address any drips immediately before full-pressure operation.

Position the splitter to minimize stress on connecting hoses and faucet threads. Avoid arrangements that create tension or twisting forces on connections. Support heavier splitters to prevent strain on faucet threads.

Maintenance and Care Tips

Regular maintenance extends splitter life and prevents performance degradation. Weekly visual inspections identify developing issues before they cause system failures. Look for corrosion signs, loose connections, or damaged washers during routine checks.

Seasonal storage protects equipment from extreme weather damage. Drain all water from the splitter before freezing temperatures arrive. Store indoors in a dry location to prevent corrosion and freeze damage.

Washer replacement maintains leak-free operation throughout the system’s life. Replace washers showing compression marks, cracks, or hardening. Keep spare washers readily available for immediate replacement when needed.

Thread lubrication prevents galling and extends connection life. Apply thin coats of plumber’s grease to male threads before assembly. Avoid petroleum-based lubricants that can damage rubber washers.

Valve exercise prevents internal corrosion and maintains smooth operation. Cycle each valve monthly to distribute lubricants and prevent mineral buildup. Full open and close cycles help maintain internal component mobility.

Pressure testing identifies developing leaks before they become problematic. Annual pressure tests under full operating pressure reveal weak points requiring attention. Address any pressure drops or flow irregularities promptly.

Common Issues and Solutions

Dripping connections typically result from worn or improperly installed washers. Replace washers and ensure proper orientation during installation. Check thread condition and clean if necessary to achieve proper seal.

Reduced water pressure often indicates internal blockages or valve problems. Disassemble the splitter and clean internal passages of mineral deposits. Valve seats may require cleaning or replacement for proper operation.

Valve operation difficulties suggest internal corrosion or mineral buildup. Regular valve cycling and proper lubrication prevent most operational issues. Severe cases may require complete valve replacement or professional service.

Thread damage prevents proper connections and causes persistent leaks. Minor damage responds to thread repair compounds or careful file work. Severe damage requires component replacement to restore proper function.

Corrosion development indicates exposure to corrosive water conditions or improper storage. Regular cleaning and proper seasonal storage prevent most corrosion issues. Advanced corrosion may require complete unit replacement.

Pressure imbalance across outlets suggests internal flow restriction or valve problems. Check for debris in individual outlet ports and clean as necessary. Internal manifold damage may require professional repair or replacement.

Performance Comparison Analysis

Water flow capacity varies significantly among different splitter designs and construction materials. Brass units typically maintain higher flow rates compared to plastic alternatives due to smoother internal surfaces and larger passage dimensions. Premium models often feature optimized internal geometry for maximum flow efficiency.

Pressure drop characteristics impact overall system performance, particularly when operating multiple outlets simultaneously. Quality splitters minimize pressure loss through efficient internal design and smooth flow transitions. Professional-grade units maintain acceptable pressure levels even under full load conditions.

Durability testing reveals significant performance differences between construction materials and manufacturing quality levels. Brass construction consistently outperforms plastic alternatives in longevity and pressure resistance. Premium manufacturing tolerances result in better sealing and longer operational life.

Temperature resistance affects seasonal usability and storage requirements. Quality brass splitters function reliably across wider temperature ranges compared to plastic units. Freeze resistance prevents damage during unexpected temperature drops and extends operational seasons.

Valve operation consistency impacts user experience and long-term reliability. Precision manufacturing results in smooth valve operation with consistent feel across all outlets. Quality control during manufacturing ensures uniform performance across individual units.

Connection reliability depends on thread quality and washer design effectiveness. Precision threading prevents cross-threading and ensures proper seal development. Quality washer materials maintain sealing effectiveness over extended periods and multiple connection cycles.

Budget Considerations and Value Analysis

Initial purchase price represents only part of total ownership costs for hose splitters. Quality units with higher upfront costs often provide better long-term value through extended life and reduced maintenance requirements. Premium materials and construction justify higher prices through superior performance.

Maintenance costs include replacement washers, lubricants, and potential repair services. Quality splitters typically require less maintenance and have lower ongoing costs compared to budget alternatives. Comprehensive warranty coverage protects against premature failures and reduces replacement costs.

Replacement frequency impacts long-term value calculations significantly. Durable brass construction may last decades with proper maintenance, while plastic units often require replacement every few seasons. Total cost analysis should include multiple replacement cycles for budget units.

Performance value considers capability improvements and time savings provided by quality equipment. Reliable operation reduces watering time and eliminates frustration from equipment failures. Professional applications may justify premium costs through improved productivity and reduced downtime.

Accessory requirements can add significant costs to basic splitter purchases. Complete kits may provide better overall value by including necessary accessories and spare parts. Separate component purchases often exceed kit pricing while providing less comprehensive coverage.

Warranty protection adds value through manufacturer support and replacement guarantees. Extended warranty coverage indicates manufacturer confidence in product durability. Professional users particularly benefit from warranty protection against premature failures in demanding applications.

Environmental Impact and Efficiency

Water conservation benefits from precise control over irrigation systems enabled by quality splitters. Individual valve control prevents overwatering and reduces waste through targeted application. Efficient water use supports environmental stewardship while reducing utility costs.

Material sustainability varies significantly between brass and plastic construction options. Brass units offer recyclability at end of life, while plastic alternatives often end up in landfills. Durability differences affect replacement frequency and total environmental impact over time.

Manufacturing impact considerations include resource extraction and processing requirements for different materials. Brass production requires mining and energy-intensive processing, while plastic manufacturing relies on petroleum resources. Life cycle analysis should consider both production and disposal impacts.

Leak prevention capabilities directly impact water conservation effectiveness. Quality sealing systems prevent waste through dripping connections and valve leakage. Proper maintenance practices maximize conservation benefits while extending equipment life.

Energy efficiency relates to reduced pumping requirements for well water systems. Efficient splitters maintain pressure with less pump cycling, reducing energy consumption. Gravity-fed systems benefit from reduced pressure losses through quality equipment.

Longevity considerations reduce total environmental impact through extended use periods. Durable construction delays replacement needs and reduces manufacturing demand. Quality equipment selection supports sustainable practices through extended service life.

Professional vs. Residential Applications

Professional landscaping demands place higher stress on equipment through continuous operation and demanding conditions. Commercial-grade splitters feature reinforced construction and higher pressure ratings to handle professional workloads. Extended warranties and service support cater to business requirements.

Residential applications typically involve lighter duty cycles with seasonal use patterns. Home gardeners can often utilize standard-duty equipment effectively while achieving satisfactory performance. Budget considerations may favor residential-grade equipment for typical home use.

Pressure requirements differ significantly between professional and residential water systems. Commercial irrigation systems often operate at higher pressures requiring robust equipment design. Residential water pressure typically falls within standard equipment operating ranges.

Flow capacity needs scale with application size and complexity. Professional installations may require higher flow rates to supply multiple high-capacity irrigation zones. Residential applications usually involve lower total flow requirements suitable for standard equipment.

Durability expectations reflect different use patterns and replacement cycle tolerances. Professional users require maximum reliability to avoid service interruptions and customer dissatisfaction. Residential users may accept occasional maintenance needs in exchange for lower costs.

Service support availability becomes critical for professional applications where downtime creates business impact. Manufacturer support, replacement parts availability, and local service options influence professional equipment selection. Residential users typically have more flexibility in replacement timing.

Seasonal Considerations and Storage

Winter storage procedures prevent freeze damage and extend equipment life significantly. Completely drain all water from the splitter assembly before temperatures drop below freezing. Water expansion during freezing can crack even brass components and destroy internal valves.

Spring startup routines ensure proper operation after storage periods. Visual inspection identifies any damage that occurred during storage or from freeze-thaw cycles. Test all valves for smooth operation and check connections for proper sealing before full operation.

Summer operation presents high-temperature challenges for some materials and designs. Quality brass construction handles extreme heat without degradation, while plastic components may soften or warp. Proper installation location can minimize temperature stress through shading or ventilation.

Fall preparation includes thorough cleaning to remove mineral deposits and organic debris. Accumulated materials can cause corrosion or blockages during storage periods. Complete drainage and cleaning prepare equipment for successful winter storage.

Extreme weather protection may require temporary equipment removal or additional covering. Severe storms, hail, or extreme temperature events can damage exposed equipment. Removable installations allow protection during dangerous weather conditions.

Storage location selection affects equipment condition during off-seasons. Dry, temperature-controlled environments provide optimal storage conditions. Avoid areas with temperature extremes, high humidity, or corrosive atmospheres that can damage equipment.

Advanced Features and Innovation

Smart valve technology integrates electronic controls with traditional mechanical splitters. Programmable timers and remote control capabilities provide automated watering schedules. Advanced systems connect to weather monitoring for adaptive irrigation control.

Pressure regulation features maintain consistent output pressure across varying input conditions. Built-in pressure reducers protect downstream equipment from excessive pressure while ensuring adequate flow. Professional systems may include adjustable pressure settings for different applications.

Quick-connect systems replace traditional threaded connections with tool-free attachment mechanisms. These systems speed installation and removal while maintaining secure connections. Professional applications benefit from rapid equipment changes and maintenance procedures.

Modular design approaches allow customization of outlet numbers and configurations. Expandable systems accommodate changing irrigation needs without complete replacement. Professional installations particularly benefit from flexible configuration options.

Anti-siphon protection prevents backflow contamination of water supply systems. Integral check valves and air gaps protect against contamination from irrigation chemicals or stagnant water. Municipal regulations may require backflow prevention in certain applications.

Filtration integration removes sediment and debris before water reaches irrigation equipment. Inline filters prevent sprinkler clogging and extend equipment life. Professional systems often incorporate multiple filtration stages for optimal water quality.

Quality Assurance and Testing Standards

Pressure testing standards ensure equipment safety and performance under normal and extreme conditions. Industry standards specify minimum pressure ratings and burst test requirements. Quality manufacturers exceed minimum standards to provide safety margins.

Material certification verifies composition and quality of construction materials. Brass composition standards ensure corrosion resistance and durability characteristics. Third-party certification provides independent verification of material properties.

Thread accuracy standards ensure compatibility across different manufacturers and equipment types. Precision threading prevents cross-threading and ensures proper seal development. Quality control testing verifies thread conformance during manufacturing.

Flow testing procedures validate internal design efficiency and pressure drop characteristics. Standardized test conditions allow meaningful comparison between different products. Performance testing identifies optimal operating conditions and limitations.

Durability testing simulates extended use conditions to predict service life expectations. Accelerated testing procedures compress years of operation into shortened test periods. Results guide warranty terms and maintenance recommendations.

Environmental testing verifies performance under extreme temperature, humidity, and corrosive conditions. Specialized testing chambers simulate harsh operating environments. Results confirm suitability for different climate conditions and applications.

Conclusion

The right 4-way hose splitter transforms garden watering from a chore into an efficient process. Quality brass construction provides the durability and reliability necessary for consistent performance across multiple seasons. Individual valve control allows precise water management while preventing waste through targeted application.

Professional applications demand premium construction and extended warranties to ensure reliable operation. The EBH Extended Handle Brass Splitter excels in demanding commercial environments with its robust construction and superior valve operation. Extended metal handles provide the leverage necessary for high-pressure applications.

Residential users benefit from balancing performance with value considerations. The Hourleey Brass Garden Hose Splitter offers premium construction with residential-friendly pricing. Included spare washers and solid brass construction provide excellent long-term value for home gardening applications.

Budget-conscious consumers find adequate performance in the Heavy Duty Brass Garden Hose Splitter without sacrificing basic functionality. Standard brass construction and compatible pricing make quality irrigation control accessible to more users. Performance meets typical residential requirements effectively.

Specialized needs such as ergonomic operation or comprehensive system setups find solutions in targeted products. The Green Handle Hose Manifold addresses comfort concerns with extended handles and improved grip surfaces. Complete kits provide comprehensive solutions for users wanting all necessary components in one purchase.

Proper installation, maintenance, and seasonal care maximize equipment value and extend service life significantly. Regular inspections, appropriate storage, and timely repairs prevent premature failures and maintain optimal performance. Quality equipment selection combined with proper care provides decades of reliable service.

Investment in quality hose splitters pays dividends through improved watering efficiency, reduced maintenance needs, and extended equipment life. Professional-grade construction handles demanding applications while providing peace of mind through reliable operation. The right splitter choice enhances gardening success while simplifying water management tasks.